The Evolution and Efficiency of Zipper Pouch Packing Machines in Modern Packaging

Feb 20,2025 / in Blog / Top ten China packaging machine manufacturing companies

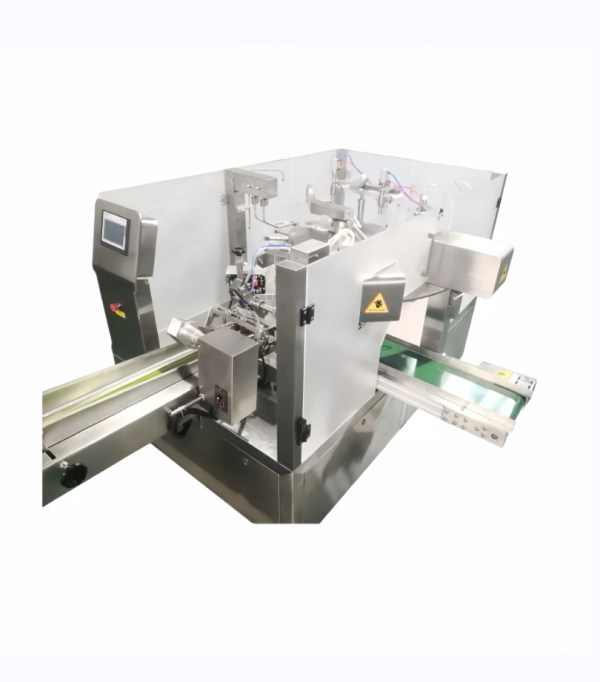

In the fast-paced world of manufacturing and consumer goods, zipper pouch packing machines have emerged as indispensable tools for businesses seeking efficiency, versatility, and product preservation. These machines specialize in packaging products—from snacks and pharmaceuticals to cosmetics and electronics—into resealable zipper pouches. This article explores the mechanics, applications, and advantages of zipper pouch packing machine, highlighting their transformative role in the packaging industry.

In the fast-paced world of manufacturing and consumer goods, zipper pouch packing machines have emerged as indispensable tools for businesses seeking efficiency, versatility, and product preservation. These machines specialize in packaging products—from snacks and pharmaceuticals to cosmetics and electronics—into resealable zipper pouches. This article explores the mechanics, applications, and advantages of zipper pouch packing machine, highlighting their transformative role in the packaging industry.How Zipper Pouch Packing Machine Works

Zipper pouch packing machine integrate advanced automation to streamline the packaging process. Here’s a breakdown of their operation:- Material Feeding: Rolls of laminated film (often multi-layered for durability and barrier properties) are fed into the machine.

- Pouch Formation: The film is shaped into pouches using heat-sealing mechanisms. A zipper strip is simultaneously inserted and sealed along the pouch’s opening.

- Product Filling: Precise volumetric or weight-based filling systems dispense the product into the pouches.

- Sealing and Cutting: The pouch is heat-sealed to ensure airtightness, then cut into individual units.

- Quality Control: Sensors detect defects, such as incomplete seals or misaligned zippers, ensuring consistency.

Key Features and Innovations of Zipper Pouch Packing Machine

Modern zipper pouch machines are designed for adaptability and precision:- Multi-Layer Zipper Integration: Machines can handle various zipper types (e.g., press-to-close, slider zippers) for customized packaging.

- Smart Automation: IoT-enabled systems monitor production metrics (e.g., speed, error rates) and enable remote adjustments.

- Hybrid Flexibility: Some models switch between zipper pouches and standard pouches, reducing downtime for manufacturers.

- Eco-Friendly Options: Machines compatible with biodegradable or recyclable films align with sustainability goals.

Zipper Pouch Packing Machine Applications Across Industries

Zipper pouches cater to diverse sectors due to their convenience and resealability:- Food and Beverage: Ideal for snacks, coffee, spices, and liquids, preserving freshness and reducing waste.

- Pharmaceuticals: Child-resistant zippers and tamper-evident seals enhance safety for pills and medical supplies.

- Cosmetics: Compact, resealable pouches are popular for travel-sized creams, serums, and samples.

- Electronics: Protect small components like cables or batteries from moisture and dust.

Advantages Over Traditional Packaging of Zipper Pouch Packing Machine

- Extended Shelf Life: Airtight seals and barrier films protect contents from oxygen, moisture, and contaminants.- Consumer Convenience: Reusable zippers enhance user experience, making products portable and easy to store.

- Cost Efficiency: Automated machines reduce labor costs and minimize material waste through precise filling.

- Brand Differentiation: Customizable pouch designs (e.g., transparent windows, vibrant prints) attract consumer attention.

Future Trends in Zipper Pouch Packaging

As industries evolve, zipper pouch machines are adapting to new demands:- AI-Driven Optimization: Machine learning algorithms predict maintenance needs and optimize filling accuracy.

- Sustainable Materials: Increased adoption of compostable films and recyclable zippers to meet environmental regulations.

- Hyper-Personalization: On-demand printing capabilities allow small-batch, customized packaging for niche markets.

- Enhanced Speed: High-speed models now produce over 200 pouches per minute, catering to large-scale production.

Conclusion

Zipper pouch packing machine represent a fusion of innovation and practicality, addressing the needs of both manufacturers and consumers. By combining automation, material science, and smart technology, these machines not only boost operational efficiency but also contribute to sustainability and brand value. As packaging demands grow more complex, the continued evolution of zipper pouch machines will undoubtedly shape the future of product presentation and preservation.For businesses aiming to stay competitive, investing in advanced zipper pouch packaging systems is no longer optional—it’s a strategic imperative.